How to Securely Store Mining Equipment and Goods

The mining industry is known for its demanding and rugged environment, where valuable equipment and goods need to be stored securely to ensure their longevity and availability when needed. Proper storage systems are crucial to protect assets from damage, theft, and deterioration. In this article, we will explore various storage solutions, including mining lockers, cabinets, and workbenches, and provide essential tips on securely storing equipment and goods in the mining industry.

Understanding the Importance of Secure Storage

A) Asset Protection Mining equipment and goods are significant investments for any mining operation. Secure storage systems play a vital role in protecting these assets from damage, wear and tear, and premature deterioration. By implementing proper storage solutions, mining companies can extend the lifespan of their equipment and goods, reducing the need for frequent replacements and repairs.

B) Safety Considerations In addition to asset protection, safety is paramount in the mining industry. Storing equipment and goods in an organized and secure manner helps prevent accidents and injuries. By ensuring that items are stored properly, mining companies can reduce the risk of tripping hazards, falling objects, or damage caused by improper handling. Adequate storage solutions contribute to a safer working environment for employees.

C) Theft Prevention Theft is a significant concern in the mining industry, given the high value of equipment and resources. Secure storage systems act as a deterrent to potential theft by providing controlled access and locking mechanisms. By restricting unauthorized access to storage areas, mining companies can safeguard their assets and minimize the risk of theft or tampering.

Mining Storage Systems

A) Mining Lockers Mining lockers are designed specifically to meet the storage needs of the industry. These lockers are constructed from durable materials that can withstand harsh mining environments, such as heavy-duty steel or impact-resistant plastics. They typically feature secure locking mechanisms, such as padlocks or keyless entry systems, ensuring that only authorized personnel can access the contents. Mining lockers come in various sizes and configurations to accommodate different types of equipment and gear.

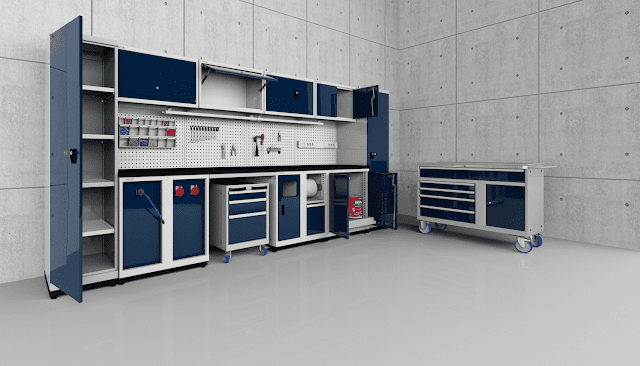

B) Cabinets and Shelving Units Cabinets and shelving units are versatile storage solutions that can be customized to meet specific mining requirements. They provide a structured and organized storage space for equipment, tools, spare parts, and other goods. Cabinets often feature sturdy construction, reinforced doors, and secure locking mechanisms to prevent unauthorized access. Adjustable shelves allow for flexible storage configurations, making it easier to store items of varying sizes. Some cabinets may also incorporate additional features like ventilation systems or hazardous material storage compartments to comply with safety regulations.

C) Workbenches and Tool Storage Workbenches are essential in mining operations, providing a designated space for equipment maintenance, repairs, and assembly. Incorporating tool storage solutions into workbenches helps keep tools organized, readily accessible, and secure. Tool cabinets or drawers with individual compartments can be integrated into workbenches, allowing for efficient organization and minimizing the risk of lost or misplaced tools. Lockable tool storage ensures that valuable tools are properly stored and accounted for.

Tips for Secure Storage in the Mining Industry

A) Inventory Management Implement a comprehensive inventory management system to keep track of equipment and goods. This includes labeling, categorizing, and documenting items stored in each storage unit. Regular inventory checks help identify missing or damaged items and prevent unauthorized removal.

B) Controlled Access Limit access to storage areas by implementing access control systems or key management protocols. Only authorized personnel should have keys or access codes to storage units. This reduces the risk of theft or unauthorized use of equipment and resources.

C) Regular Maintenance and Inspections Perform routine inspections of storage systems to ensure their integrity and functionality. Replace worn-out locks, hinges, or other components promptly. Regular maintenance helps prevent security vulnerabilities and prolongs the lifespan of storage units.

D) Proper Handling and Stacking Train employees on proper handling and stacking techniques to avoid damage to equipment and goods during storage. Consider using protective padding or racking systems to prevent scratching or impact damage.

E) Environmental Considerations Take environmental factors into account when storing equipment and goods. Extreme temperatures, humidity, or corrosive substances can damage sensitive equipment or degrade materials. Use climate-controlled storage areas or consider specialized storage solutions to mitigate these risks.

Conclusion

Secure storage of equipment and goods is crucial in the mining industry to protect valuable assets, ensure safety, and prevent theft. Mining lockers, cabinets, workbenches, and other storage solutions provide the necessary infrastructure to achieve these goals. By implementing secure storage systems and following best practices, mining companies can enhance asset protection, improve safety conditions, and optimize their operational efficiency in a challenging mining environment.

Comments

Post a Comment